Release time: May 13, 2023

Views: 2530

With the deepening of modern medical research and the continuous updating of medical instruments, semiconductor cooling technology has been widely used in medical instruments, bringing good news to human beings. Today, Huajing will introduce several high-end instruments using semiconductor cooling technology, and see how semiconductor cooling technology has become a key technology supporting many modern industries by itself own power!

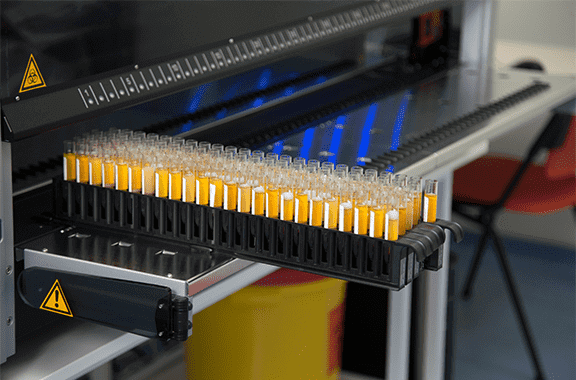

1. PCR Instrument

PCR technology (polymerase chain reaction) is a method of synthesizing specific DNA fragments by enzymatic reaction. It consists of a thermal cycle consisting of three temperature steps, namely high temperature denaturation, low temperature annealing, and suitable temperature extension. Therefore, the PCR instrument is actually a program temperature control instrument, also known as a gene amplification instrument. The effect of the PCR instrument is closely related to the transition time between temperature steps. The shorter the time, the higher the amplification specificity and the better the effect. The key technology is to increase the temperature rise (fall) speed of the sample. Using ordinary cooling (heating) methods, such as compressor cooling, water cooling, air cooling, infrared heating, electric wire heating, etc., it is very difficult to achieve a better amplification effect; while the PCR instrument using semiconductor cooling technology can not only achieve good results. It also has the advantages of small volume, no noise, and large temperature adjustment range. This is also the technical core of many high-end PCR instruments.

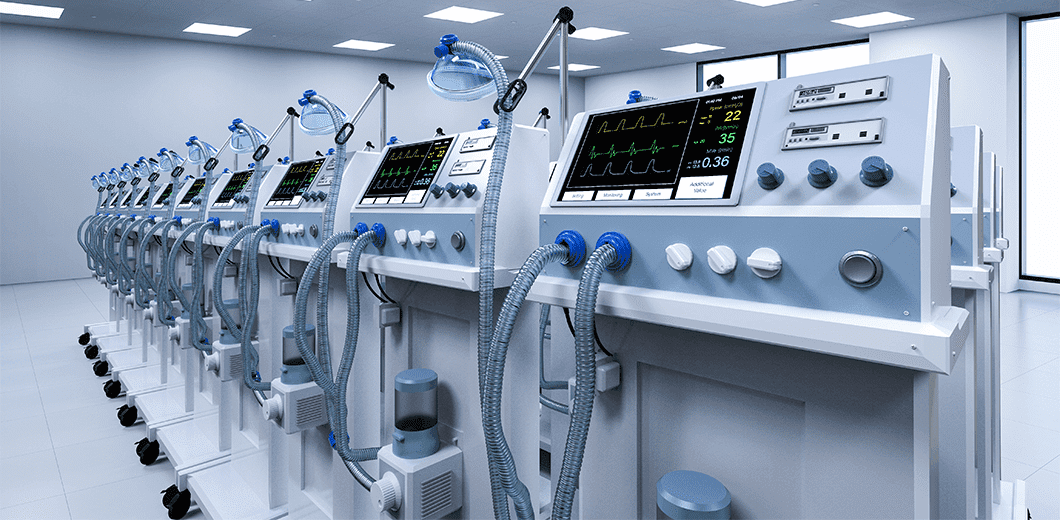

2. Ventilator Air Pump

The ventilator air pump is an important spare part in all ventilators, especially in hospitals that do not use the central air supply method to provide positive air pressure, it is an essential spare part. Used to supply dry, clean gas to the ventilator. Generally, after the gas is cooled down, the condensed water will be separated by a water separator to achieve the purpose of drying the gas. Compared with the ordinary domestic air pump of air cooling, the air pump using semiconductor cooling technology has the advantages of small volume, simple structure, no noise, fast condensation speed and high condensation efficiency. Therefore, it is widely used in high-end ventilator air pumps.

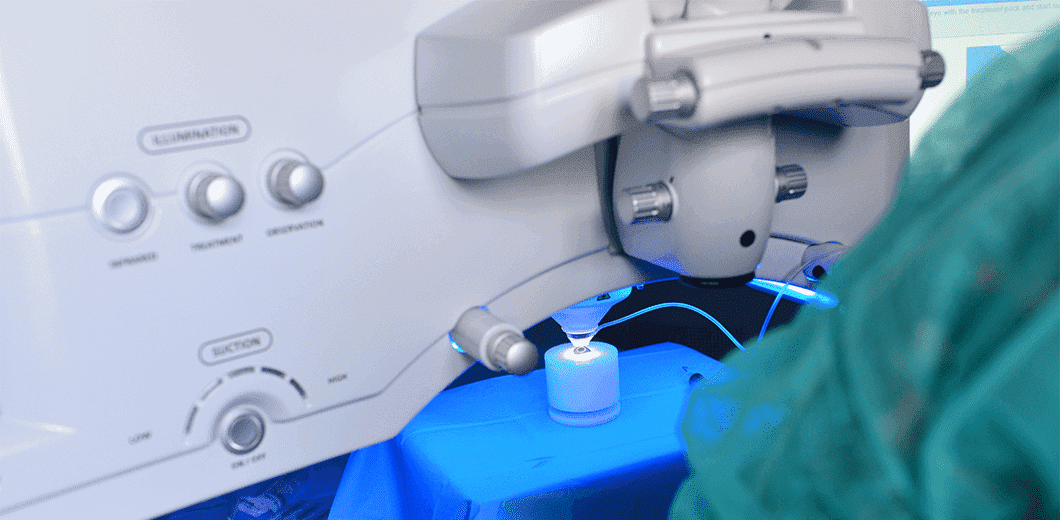

3. Nd-YAG Laser Surgery Device

The biggest feature of Nd-YAG laser surgical instrument is its high output power, which can gasify or cut diseased cells. In addition, the ulcer tissue and tumor tissue treated by Nd-YAG laser are immune to the ulcer or tumor and will not recur. Therefore, it has been widely used in clinical treatment in recent years. The output power is large, and the electrical power consumed is correspondingly large. Taking the commonly used 100WNd-YAG laser surgery device as an example, the electrical power consumed is as high as 35KW or more, and only a small part of such a large amount of energy is converted into light energy. Most of the energy is converted into heat energy. If the heat dissipation is not sufficient, the laser cavity, the internal YAG crystal and the xenon lamp will be damaged. Therefore, sufficient heat dissipation of the laser cavity is a prerequisite for ensuring the normal operation of the Nd-YAG laser surgical instrument.

At present, most of the Nd-YAG laser surgical instruments, whether domestic or imported, use water-cooling to cool the laser cavity, which also leads to the common disadvantages of complicated water pipe connection, large volume, cumbersome operation, and short continuous working time. However, Nd-YAG laser surgery device of using the semiconductor cooling, the cooling system of volume is small and light in weight, which can realize integrated design, the whole set of components of the surgical instrument, including electricity, laser cavity, temperature control circuit, semiconductor cooling system, etc., are all assembled together, and there are no auxiliary accessories such as external water tank and external water pipe. The volume is small, light in weight, and extremely convenient to use. At the same time, the continuous working time is very long. When the output power is less than 40 watts, the continuous working can be basically unlimited.

4. Frozen slicer

The ordinary slicer uses CO₂ as the refrigerant, the temperature can only reach about -10 ℃, and the cooling speed is not fast, and it needs to be hold on to treatment before freezing to ensure that the tissue cells are not damaged. Therefore, the slicing process takes a long time. Especially when the ambient temperature is high, the freezing hardness of the tissue directly affects the tissue sectioning effect, and the tissue hardness decreases with the increase of the tissue temperature. In addition, if the freezing speed is not high enough, the phenomenon of slice ice crystals or tissue cell rupture will occur, which will affect the slice quality. However, the slicing process of frozen slicer that uses semiconductor cooling technology to freeze tissue only requires two processes: freezing and slicing. The tissue freezing speed is high and the temperature is low, and the tissue temperature can be reduced to -50℃~-60℃ within a few minutes. It has the advantages of simple and convenient operation, fast slicing speed and high quality.

To sum up, Huajing briefly introduced several medical devices using semiconductor cooling technology. In recent years, semiconductor cooling technology, as an important technical solution for local active cooling and precise temperature control with high heat flux density, has been widely used in many fields such as consumer electronics, communication, medical beauty, industry, automobile, aerospace and defense, oil and gas mining and so on. And with its irreplaceable flexibility, diversity, reliability and other advantages and characteristics, it has become a key technology supporting many modern industries.

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright