On the basis of market, Huajing focuses on the exploitation and design of innovative products, it pays, attention to link market with sources to proceed the design and exploitation of thermal projects.

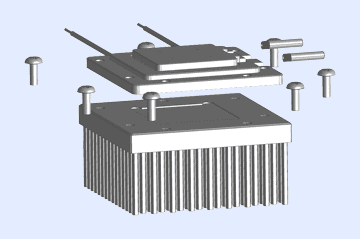

Industrial design is not about creating appearance, but creating relationships, and structural design relates to the good or bad productization. Through research and customer needs, accurate positioning, clear design ideas, efficient design communication, designers innovate from modeling, color, ergonomics, materials, processes, molding, assembly, etc. to achieve optimal design results.

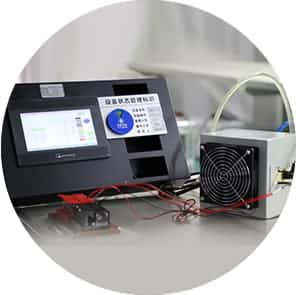

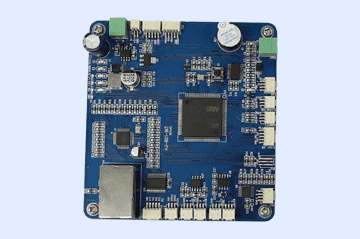

In response to different customer needs, Huajing cooperates with external electronic design companies to develop and achieve rapid realization of customer products, early market entry, and seize the market opportunity.

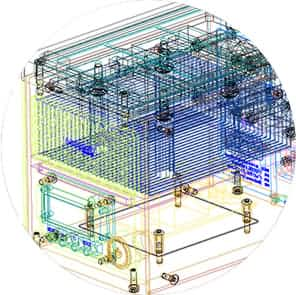

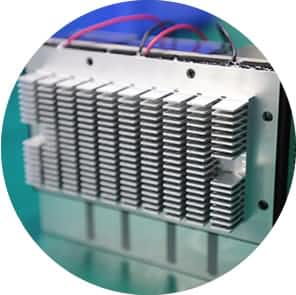

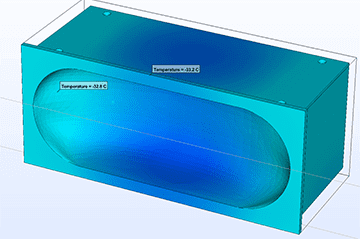

In the preliminary given heat dissipation environment, Huajing designers will first evaluate the feasibility of the overall machine's heat dissipation, preliminarily complete the wind channel design and fan selection, complete the heat sink design; and finally perform the overall machine thermal simulation again to optimize the previous wind channel design and fan selection.

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright