Release time: August 07, 2025

Views: 348

Optimizing Bioreactor Performance with Advanced Thermal Management Technology

Key Temperature Control Challenges in Biopharmaceutical Applications

Modern biopharmaceutical production and research laboratories rely heavily on precise bioreactor temperature management, where even minor fluctuations can significantly impact:

Cell viability and growth rates

Protein expression yields

Product consistency and quality

The industry faces four primary temperature control challenges:

Extreme Precision Demands: Most biological processes require temperature stability within ±0.1°C, with some sensitive applications needing ±0.05°C.

Dynamic Thermal Loads:Metabolic heat generation varies dramatically throughout fermentation cycles, requiring real-time compensation.

Space Optimization: Modern laboratories demand compact thermal solutions that don't compromise performance.

Continuous Operation Reliability:Many bioprocesses run uninterrupted for weeks, requiring fail-safe temperature regulation.

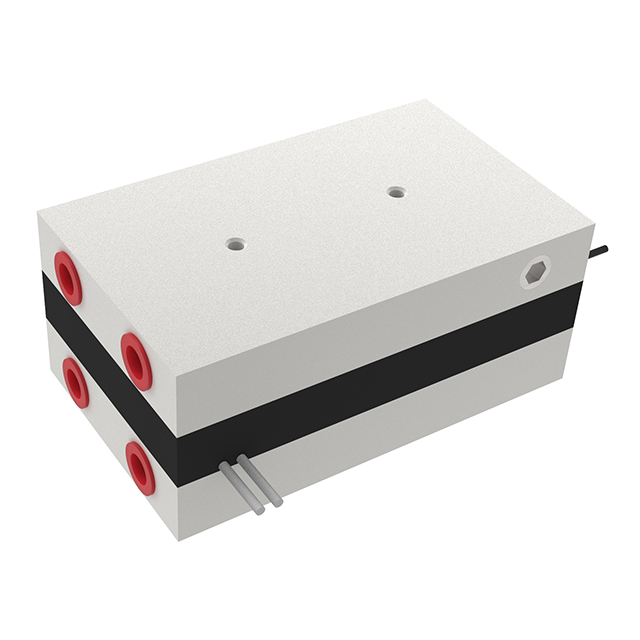

Our liquid cooling system delivers industry-leading performance:

Unmatched ±0.05°C temperature stability

Pharmaceutical-grade corrosion-resistant materials

<30 dB operation for vibration-sensitive environments

Seamless integration with all major bioreactor brands

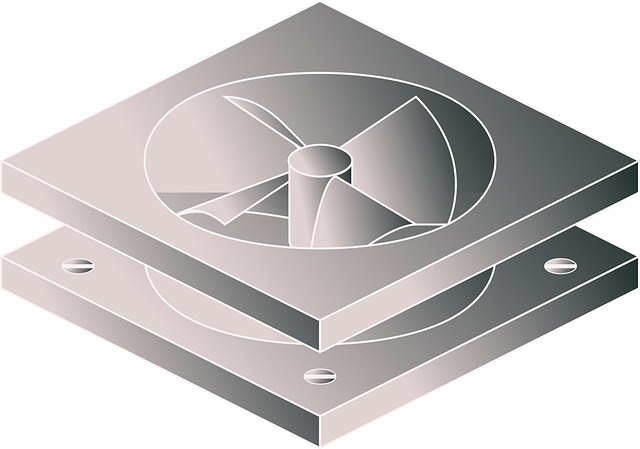

For constrained laboratory spaces, our slim-profile plate system provides:

Industry's thinnest 25mm profile

Sub-30 second temperature adjustment

Advanced predictive PID algorithms

Ideal for micro-bioreactors and perfusion systems

Huajing solutions have been validated in demanding bioprocessing environments:

Monoclonal Antibody Production: Maintained ±0.1°C for 45 days in 5,000L bioreactors, increasing titer by 18%.

Vaccine Manufacturing: Achieved FDA-compliant temperature control in GMP-grade facilities.

Continuous Fermentation: Enabled 97% uptime in year-round industrial enzyme production.

Achieved FDA-compliant temperature control

GMP-grade semiconductor cooling systems

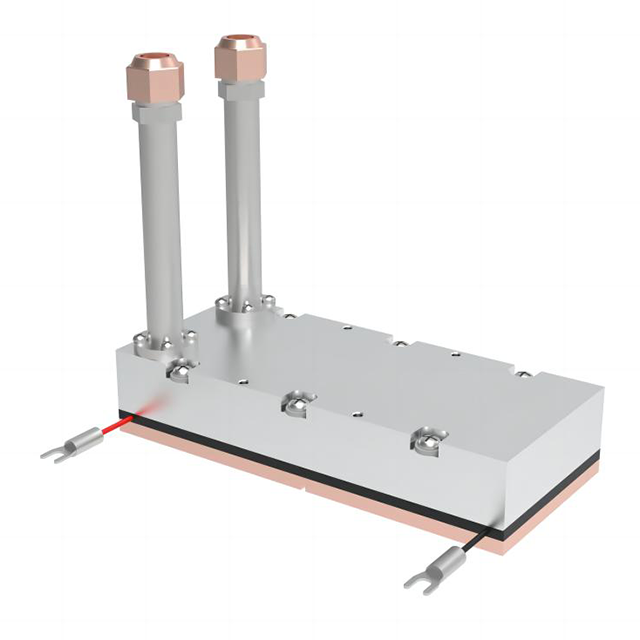

Advanced Semiconductor Cooling Technology: 35% more efficient than standard Peltier devices

Smart Temperature Regulation: Adaptive control algorithms

Optimized Thermal Performance: CFD-validated heat exchanger designs

Custom Bioreactor Solutions: Application-specific engineering

AI-powered predictive thermal control systems

Single-use bioreactor integration kits

Industry 4.0 compliant smart monitoring solutions

Contact our temperature control specialists for your bioreactor cooling requirements.

All systems utilize Huajing's proprietary semiconductor cooling technology for reliable, precise temperature regulation.

Contact us: sale02@hj-tc.com

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright